![]()

Excellent Quality Cable Tray Roll Double layer Forming Machine

Basic introduction 1.The ladder type cable traysproduced by this roll forming machine are used widely in the field of petrol oil industrychemical industrytelevision and telecommunications with advantages of light-weightlow costsbig lo

Send InquiryChat Now

电 话: +86-15961895852

E-mail:

sales@kehengmixing.com

Product Details

Basic introduction

1.The ladder type cable trays,produced by this roll forming machine, are used widely in the field of petrol oil industry,chemical industry,television and telecommunications with advantages of light-weight,low costs,big loading,easy assembling.heat radiation and so on. it is suitable to lay large diameter cable trays( power cable tray) ,especially for high and lower voltage powered cable trays.

2.Without dismantling any machine parts and controlled by PLC the cable tray roll forming machine can achieve the size change between 100-600mm automatically while

3.The mould change is switched by adjusting the combination mould and holes punching,length cutting is completed at one-time and the whole production process is fast,stable with security.

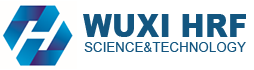

Profile Drawing

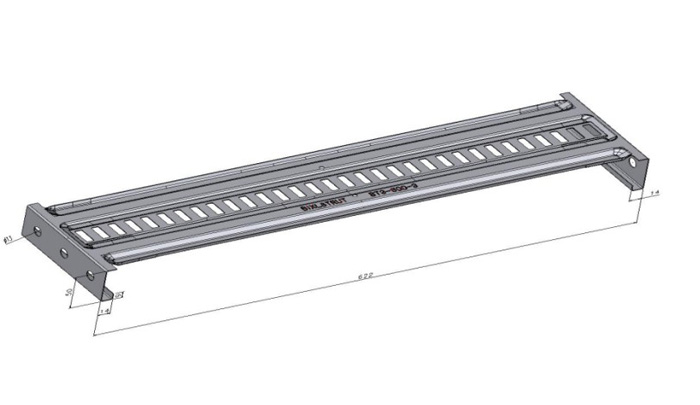

Process flow:

3T Hydraulic de coiler--Leveling--Servo feeder--200T Punching press--pit ---Roll Forming- Flying shear with end expand- Output tables

Main technical parameters

1.Raw material request:G350-G450Mpa cold rolled or hot rolled steel,galvanized steel

2.Material thickness:0.5mm-1.0mm

3.Whole line working speed:14m/min

4.We adopt cantilever type machine structure

5.20 forming stations

6.Motor power:2x11kw Siemens brand

7.Material max. thickness:0.8-1.5mm

8.The diameter of the shaft:75mm

9.Rollers material: GCr15,quenching treatment:HRC58-62°

10.Material of shaft:40Cr heat treatment

11.Driving system:chain drive 1.2”HRB brand made in China

12.With fully automatic adjustment from one width to another width it just needs few seconds to finish changing:

Width from 50mm to 200mm: we use 1x 2.2KW motor.

Whole line components list

|

3 Ton hydraulic decoiler with control box and hydraulic station

|

1 set

|

|

Leveling machine

|

1 set

|

|

Servo-feeder and control cabinet

|

1 set

|

|

200T punching press

|

1 set

|

|

Punching mould for cable tray 50-200mm width

|

1 set

|

|

Punching mould for cable tray 50-100mm height

|

5 sets

|

|

PLC control box(main forming machine)

|

1 set

|

|

50-100x50-200mm Full automatic roll forming machine

|

1 set

|

|

Flying shear with servo-motor control

|

1 set

|

|

Cutting blade with end-expand

|

1 set

|

|

Hydraulic station for cutting

|

1 set

|

|

Outables

|

2 pcs

|

|

|

|

|

hydraulic decoiler |

Pinch leveler |

Servo feeder hydraulic punching mechanism |

|

|

|

|

Cable tray cover plate forming mechanism |

Cable tray roll forming machine |

Electric control system |

Company Profile

Wuxi HRF Science & Technolog Co.,Ltd located in Wuxi city,Jiangsu province which is close to Shanghai international airport ,we enojoy convenient transportation and advantageous location with which supply good business opportunities for the investors home and abroad.And our company was established in 2009, has the specialized technical team, provides the high quality product and the high quality service for you.

Our company are specialized in designing,manufacturing,sales and services in the field of cold roll forming machines, we can supply the stud-track forming machines,c/z purlin forming machines,roof &wall forming machines,expressway guardrail forming machines, metal deck forming machines ,steel tile forming machines ,PU sandwich panel production line as well as slitting lines and cut-to-length machines lines and so on.

"Copra" software made in Germany is a kind of professional software for designing the cold roll forming machines.In the past years,we devoted ourselves to studying,training and putting into production.Through continous efforts made by our staffs,we already improved a lot on the machines quality and won good repution in the worldwide.

We are ready to establish the business relations with the overseas customers and we also believe" the oppotunity here,here you are"

Our commitment is quality and service , our goal is customer satisfaction . We will, as always, be pragmatic and promote mutually beneficial cooperation and common development Of you

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

3. What is the quality of your machine?

The first class Quality. We manage to offer our partners the best customer care, products and services by using the latest technologies in the branch. The components we provide are of best quality, to make sure our machines can be running very well for decades.

4. What service we can get from your company?

-VIP Service. Due to our standards, we manage to build long-lasting relationships with all our customers. We are 24/7 online available for you to answer your questions and solve your problems.

5. Quality Inspection

The machines of our company have many certificates like ISO 9001, CE, SGS, etc. Before the shipping, we have a series of quality check system, includes 3 times of inspection for every production procedure. First inspection needs the workers to check and sign on the test report. Second inspection involves department leaders to check and sign on the test report. The Third inspection needs professional inspector to check and ensure the machines are qualified. We also give 18 month warranty time to the customer

Related Products

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing. E-mail:

E-mail: Tel

Tel  Add

Add