![]()

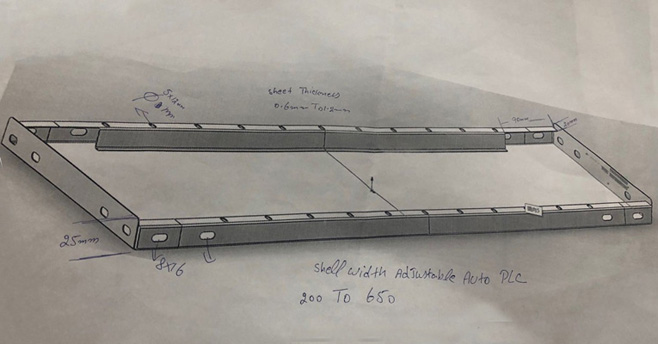

25x200-650 Automatic Adjustable Shelf Panel Forming Machine

Description Function Cross beam shelf structure: A, column: crossbeam shelf (cargo position shelf) is composed of two columns, transverse brace and oblique brace connected by nylon self-locking bolt. The combined structure effectively pre

Send InquiryChat Now

电 话: +86-15961895852

E-mail:

sales@kehengmixing.com

Product Details

Description &Function

Cross beam shelf structure:

A, column: crossbeam shelf (cargo position shelf) is composed of two columns, transverse brace and oblique brace connected by nylon self-locking bolt. The combined structure effectively prevents the shelf instability after bolt loosening. There are double row diamond holes on the column, and the hole pitch is 75mm or 50mm, so the beam can be freely adjusted up and down on the column by 75mm or 50mm. The section of the column is composed of 11 times 13 faces, with large inertia distance, strong bearing capacity and strong impact resistance. The cross beam shelf column adopts automatic punching and then cold bending forming technology, which avoids the possible exit of the column due to the stress concentration of the column. At present, the crack fails. In order to prevent the collision of forklift, it is generally equipped with column protection.

B, crossbeam: the crossbeam shelf (freight shelf) is welded together by two column cards and crossbeam poles. The crossbeam is welded by two special type welding beams, which thickens the thickness of the upper and lower parts of the crossbeam. According to the design theory of steel structure, this structure makes full use of the load resistance capacity of the material, and has the characteristics of light weight, strong bearing capacity and low cost. When the beam is connected to the column, it is equipped with a specially designed safety pin with ear piece, which can not be easily pulled out, which can ensure that the beam will not fall off after the impact of external force. Heavy shelf is also called bracket. Disc shelf has the characteristics of heavy bearing, wide range of high adaptability, mechanical access, high selection efficiency and so on, but the space utilization rate is general. L can store a wide range of items, with pallets and accessories, can solve the access problem of most materia.This equipment can be used in large shopping malls, supermarkets, as well as factory warehouses.

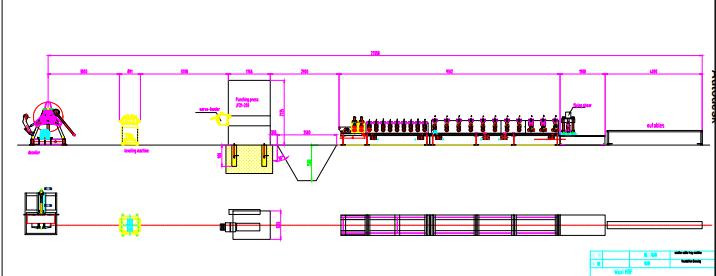

The whole lineflowchart

5T manual decoiler--ribs pressing –-lateral holes punching --corner cut(42mm)--corner cut ( 52mm)--logo stamping ------Roll Forming---hydraulic cutting&bending combination mould---Output tables

Main technical parameters

Finished products:box panel with ribs in the middle

1. Raw material request:G350Mpa cold steel or galvanized steel

2. Material thickness:0.4mm-1.2mm

3. Whole line working speed:3-5m/min

Whole line components list

|

4. NO. |

5. Name |

6. QTY |

7. Remark |

|

8. 1 |

9. 5Tmanual decoiler |

10. 1 set |

11. Max 5T

12. Max coil:800mm

13. Manual expansion and manual decoiling

14. |

|

15. 2 |

16. Ribs pressing |

17. 1 |

18. 1;Motor:5.5kw

19. Hydraulic control the ribs position

20. Hydraulic motor:5.5kw |

|

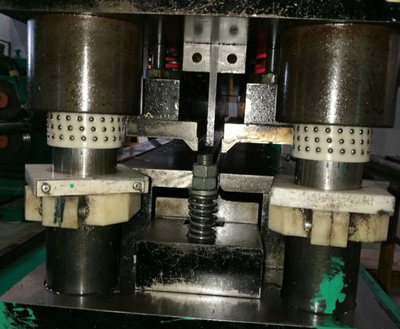

21. 4 |

22. holes Punching & corner cut |

23. 1 set |

24. We use hydraulic punching machine

25. Corner cut mould:2 sets( 42mm and 52mm including vertical connection hole)

26. Corner cut 90mm : 1 set

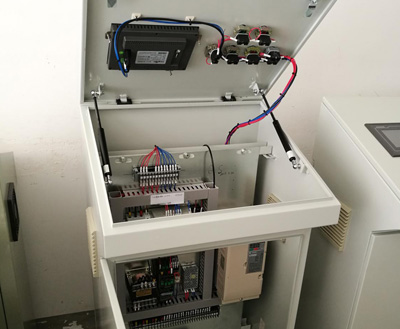

27. Lateral holes punching mould: 1 set

28. Logo stamping mould: 1 set |

|

29. 6 |

30. Roll forming Machine |

31. 1 set |

32. 1)wall panel structure

33. 2) 24 forming stations

34. 3)15KW motor made in China

35.

36. |

|

37. 7 |

38. Hydraulic Cutting&bending mould combination |

39. 1 set |

40. Cutting power:7.5kw

41. Mould material:Cr12.HRC58-62 |

|

42. 8 |

43. Run-out table |

44. 2pcs |

45. 1)Steel frame with Rollers |

|

46. 9 |

47. Electric control panel |

48. 1 set |

49. PLC control system ,Siemens from German brand

50. Yaskawa inverter from Japan |

|

51. 10 |

52. Hydraulic system |

53. 1 set |

54. Solenoid is made in China |

Hydraulic punching press machine and punching moulds

Product Advantage

1.Technological process of the production line is concise, compact layout, advanced technology, put an end to produce defects, comprehensive energy consumption is low, simple operation and maintenance, low operating cost.

2.Production line adopts the standard electrical, instrumentation components and equipment components meet the needs of the buyers,Control system has the maintainability and expansibility; And ensure the advanced technology, reliable control, during normal operation can automatic complete all real-time detection and adjusting function, have interlocking function to prevent wrong operation, Do all the operation, monitoring on main operating platform .Display and handle the alarm.

Company Profile

Wuxi HRF Science & Technolog Co.,Ltd located in Wuxi city,Jiangsu province which is close to Shanghai international airport ,we enojoy convenient transportation and advantageous location with which supply good business opportunities for the investors home and abroad.And our company was established in 2009, has the specialized technical team, provides the high quality product and the high quality service for you.

Our company are specialized in designing,manufacturing,sales and services in the field of cold roll forming machines, we can supply the stud-track forming machines,c/z purlin forming machines,roof &wall forming machines,expressway guardrail forming machines, metal deck forming machines ,steel tile forming machines ,PU sandwich panel production line as well as slitting lines and cut-to-length machines lines and so on.

"Copra" software made in Germany is a kind of professional software for designing the cold roll forming machines.In the past years,we devoted ourselves to studying,training and putting into production.Through continous efforts made by our staffs,we already improved a lot on the machines quality and won good repution in the worldwide.

We are ready to establish the business relations with the overseas customers and we also believe" the oppotunity here,here you are"

Our commitment is quality and service , our goal is customer satisfaction . We will, as always, be pragmatic and promote mutually beneficial cooperation and common development Of you

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

3. What is the quality of your machine?

The first class Quality. We manage to offer our partners the best customer care, products and services by using the latest technologies in the branch. The components we provide are of best quality, to make sure our machines can be running very well for decades.

4. What service we can get from your company?

-VIP Service. Due to our standards, we manage to build long-lasting relationships with all our customers. We are 24/7 online available for you to answer your questions and solve your problems.

5. Quality Inspection

The machines of our company have many certificates like ISO 9001, CE, SGS, etc. Before the shipping, we have a series of quality check system, includes 3 times of inspection for every production procedure. First inspection needs the workers to check and sign on the test report. Second inspection involves department leaders to check and sign on the test report. The Third inspection needs professional inspector to check and ensure the machines are qualified. We also give 18 month warranty time to the customer

Related Products

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing. E-mail:

E-mail: Tel

Tel  Add

Add