Wuxi HRF Science & Technology Co.,Ltd

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

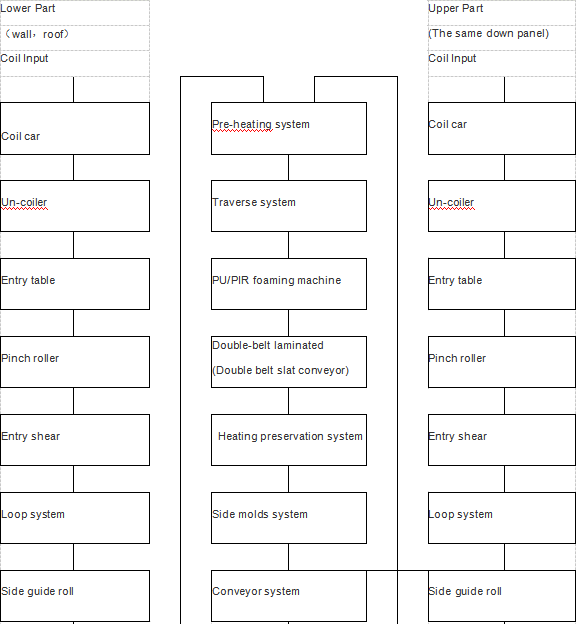

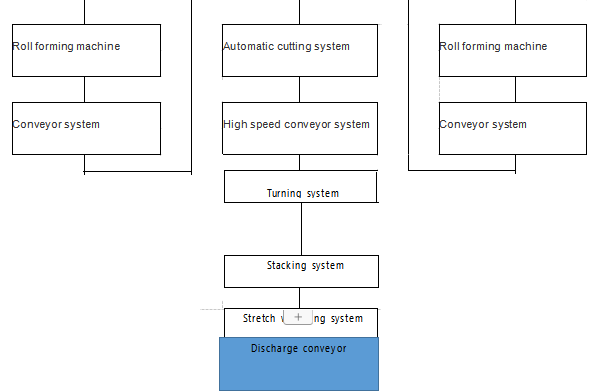

| Name | Quantity | Configuration | Reference Picture | |||

| 1.Top Layer roll forming machine |

|

|||||

| 1.1 Coil forming line | 2 sets | Capacity:8tons |

|

|||

| 1.2 Uncoiler | 1set |

A.Arm type B.Capacity:8tons C.Protection film device |

||||

| 1.3 Up-down entry table | 1set | Roller&Guide | ||||

| 1.4 Pinch roller | 1set | Rubber coated roller | ||||

| 1.5 Entry shear | 1set | Hydraulic type | ||||

| 1.6Loop system | 1set | Electrical system | ||||

| 1.7 Roll forming system | 2 sets | |||||

| 1.8Upper conveyor | 1set | Cr.coated rollers | ||||

| 1.9 Platform system | 1set |

Steel structure Ladder & Handrail |

||||

|

2.Bottom Layer roll forming machine |

|

|||||

| 2.1 Coil car | 1set |

Capacity:8tons |

|

|||

| 2.2 Uncoiler | 2 sets |

A.Arm type B.Capacity:8tons C.Protection film device |

||||

| 2.3 Up-down entry table | 2 sets | Roller&Guide | ||||

| 2.4 Pinch roller | 2 sets | Rubber coated rollers | ||||

| 2.5 Entry shear | 2 sets | Hydraulic type | ||||

| 2.6 Overlapping device | 1set | Electrical system | ||||

| 2.7 Roll forming system | 1 set | The same down panel style for wall ,roof | ||||

| 3.Upper conveyor table | ||||||

| 3.1 | 1set | A.for upper roll forming machine |

|

|||

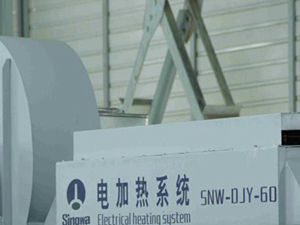

| 4.Pre-heating system | ||||||

| 4.1 | 1set | Electrical heating system |

|

|||

| 5.Traverse(Portal) system | ||||||

| 5.1 | 1set |

Import mixed spear Servo mobile Sliding table AC servo system Customization pipe |

|

|||

|

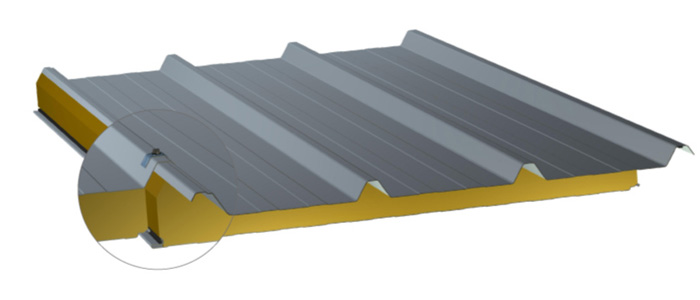

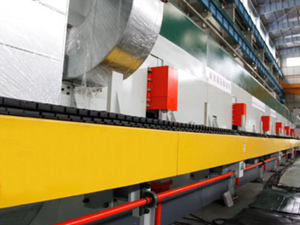

6.Double-belt laminated (Double belt slat conveyor) |

||||||

| 6.1 | 1set |

Useful length:24m structure:steel H+Heat treatment +CNC machine Turbine and Screw system Power from motor Aluminium and steel device Full heat preservation inner system Single motor drive |

|

|||

| 7.Double-belt laminated heating system (Double belt slat conveyor heating system) | ||||||

| 7.1 Heating system | 1set |

Total power: 190KW Electrical heating (or fuel oil heating) C.include full fuel oil system |

|

|||

| 7.2 Heating preservation | 1set |

Overall shield Inner heating preservation |

||||

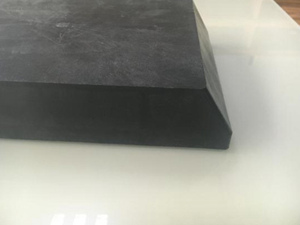

| 8.Side molds system 3 | ||||||

|

No.1 roof 50mm-100mm (50/75/100) |

6 sets |

Nylon |

|

|||

|

No.2 wall 50mm-100mm (50/75/100) |

6 sets |

Nylon | ||||

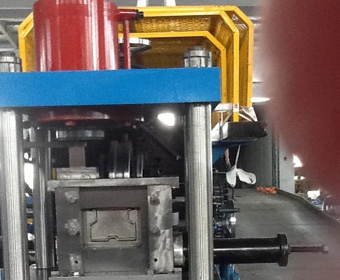

| 9.Automatic cutting device | ||||||

| 9.1 | 1set |

Band saw device Encoder Servo system Dedusting system Synchronization system Thickness:30mm-80mm |

|

|||

| 10.Conveyor system | ||||||

| 10.1 | Full sets |

Gear ,chain drive The longest:15mm |

|

|||

| 11.Electric control system | ||||||

| 11.1 | 1set |

PLC+ touch screen Linkage control system Concentrated control system |

|

|||

Product Advantage

1.Technological process of the production line is concise, compact layout, advanced technology, put an end to produce defects, comprehensive energy consumption is low, simple operation and maintenance, low operating cost.

2.Production li ne adopts the standard electrical, instrumentation components and equipment components meet the needs of the buyers,Control system has the maintainability and expansibility; And ensure the advanced technology, reliable control, during normal operation can automatic complete all real-time detection and adjusting function, have interlocking function to prevent wrong operation, Do all the operation, monitoring on main operating platform .Display and handle the alarm.

|

|

|

|

|

|

Company Profile

Wuxi HRF Science & Technolog Co.,Ltd located in Wuxi city,Jiangsu province which is close to Shanghai international airport ,we enojoy convenient transportation and advantageous location with which supply good business opportunities for the investors home and abroad.And our company was established in 2009, has the specialized technical team, provides the high quality product and the high quality service for you.

Our company are specialized in designing,manufacturing,sales and services in the field of cold roll forming machines, we can supply the stud-track forming machines,c/z purlin forming machines,roof &wall forming machines,expressway guardrail forming machines, metal deck forming machines ,steel tile forming machines ,PU sandwich panel production line as well as slitting lines and cut-to-length machines lines and so on.

Company Profile

Wuxi HRF Science & Technolog Co.,Ltd located in Wuxi city,Jiangsu province which is close to Shanghai international airport ,we enojoy convenient transportation and advantageous location with which supply good business opportunities for the investors home and abroad.And our company was established in 2009, has the specialized technical team, provides the high quality product and the high quality service for you.

Our company are specialized in designing,manufacturing,sales and services in the field of cold roll forming machines, we can supply the stud-track forming machines,c/z purlin forming machines,roof &wall forming machines,expressway guardrail forming machines, metal deck forming machines ,steel tile forming machines ,PU sandwich panel production line as well as slitting lines and cut-to-length machines lines and so on. Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.○ Cable Tray Forming Machine

○ Door Frame Forming Machine

○ Guardrail Forming Machine

○ Pipe Forming Machine

○ Purlin Quick-Changeable Forming Machine

○ Rack Roll Forming Machine

○ Cotinuous Pu Panel Press Line

○ Discotinuous Pu Panel Press Line

○ Automatic Rotary Shear Machine

○ High Speed Uncoiling-Leveling-Cut To Length -Stacking Line

○ Hr Coil Uncoiling-Leveling Cut To Length Stacking Line

○ High Speed Uncoiling - Slitting Rewinding Line

○ Uncoiling - Slitting - Rewinding Line For Middle &Heavy Thickness

E-mail:

E-mail: Tel

Tel  Add

Add