![]()

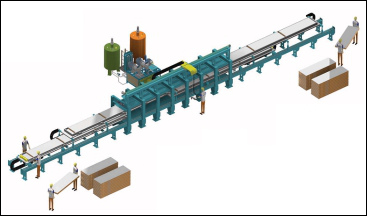

12m Discontinuous PU sandwich panel machine

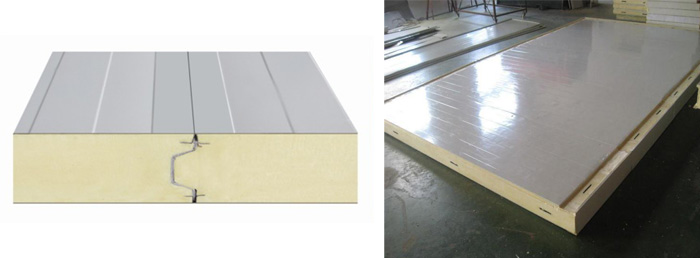

product description PU sandwich panel production line is used for continuous production of sandwich panels double side is flexible material with polyurethane or Phenolic inside . The main products of this line are exterior wall insulation

Send InquiryChat Now

电 话: +86-15961895852

E-mail:

sales@kehengmixing.com

Product Details

product description

PU sandwich panel production line is used for continuous production of sandwich panels, double side is flexible material with polyurethane or Phenolic inside . The main products of this line are exterior wall insulation composite panel and duct of central air-conditioner. It’s working principle is : four component of regid foaming material according to a certain ratio deliveried to mixing head by metering pump of high pressure foaming machine, and distributed even on the bottom sheet of lower sandwich panel, deliveried with upper coil to the double belt laminating conveyor at the same time. Regid foam blowed and solidified to shape during the upper and lower conveying chain plate. The shapped sandwich panel cut to a certain prodution desired length products by cutting machine on produciton line.

The whole lineflowchart

Cold storage roll forming include 5Ton manual un-coiler, transmit device, roll forming (include feeding guide),cutting after roll forming, hydraulic system, electric control system and finished panel supporting arm. Passive uncoil--feeding-- - forming -finished products The type pursues board (basis on customer’s require to design)

Main technical data

1.Size of sheet (mm):1200mm

2.Working speed:10—14m/min

3.Roller station:16 stations

4.Diameter of roller:75mm

5.Material of rolls:45#,polished and coated with chrome

6: Headstock:High quality 45# high carbon steel , 6.Roller diameter:Ф75mm

7.Main power:7.5 kw

8.Hydraulic station motor power:11kw

9.Hydraulic pressure: 15Mpa

10.Electrical control system: PLC control (Panosonic)

11.Dimension: 7300×1600×1200mm

12.Material of cutting: Cr12Mov

13.Thickness: 0.3 mm---0.8mm

14.Tolerance of length:3m±1.5mm

15.Weight: 6.5Ton 16.Dimension: 8500*1650*1300

I. Summary

The 2+2 layer press machine is used for discontinuous sandwich panel production line as well it can provide the reliable guarantee for producing the qualified sandwich panel.

II. Main Configuration and Technical Specifications

Main Configuration:

Ø Bilateral sides layer press machine 1 set

Includes machine frame, backboard, electrical cabinet, hydraulic

control system

Ø Rails and machine frame 1 set

Ø Heating system 1 set

III. Technical Specifications Description

Main Layer Press Machine

1. Portal Frame

It is the main loading part of the sandwich panel foaming sprayer, the machine frame is welded with superior structural steel which meets the design requirements.

2. Backboard (supporting plate)

Made of steel beams welded, whose function is to bear the upper mould and bottom mould, which can be lowered or lifted by the hydraulic system. It is processed as a whole which offers high stability and flatness.

3. Bottom Base

It is welded with superior structural steel firmly and solidly.

Backing Board Conveyor Rolls

The rails for backboard going in or out are installed with necessary room, water-pipes, electricity lines, and so forth.

The rails are separated, and when the mould is locked part of the rails are lifted while the remaining part of the rails is kept still.

4. Synchronous Mechanism Organ

In order to avoid non-synchronous operation, especially in the length while the hydraulic cylinders work, the organ guarantees the cylinders to work synchronously. The layer press machine has a mechanism to make the gears, gear racks synchronous to avoid damage of the cylinders

5. Fixed Backboards

The backboards which are welded with fine art processed hard steel, reach the grade and rigidity requirements needed during the polymerization phase (foaming).

The working surface after mechanical processing, of which the high-precision leveling is one of the most important conditions, guarantee the PU sandwich panel quality.

The cycle-heated pipe is arranged inside the backboards.

6. Mobile Backboards

As main part of the layer press machine, there are 4 pieces of bilateral side mobile backboards, which can move freely in or out.

The art design guarantees the arrangement of the heater cycle hose as in the upper backboard.

Mobile Backboards IN-OUT Drive System

The mobile backboards are motor driven, and it can move freely in or out according to design.

7. Hydraulic System

For the hydraulic system, a low-pressure drive and high pressure protection is adopted to realize the die-locking action, and to save space and energy.

The pressure compensation is automatically accomplished by the switches, and sets the safety and protection system. The oil tank is placed on the ground, and all the valves are installed on the tank as a whole, being easy to installed and maintain.

The returning oil pressure is 0.2-0.3 MPa, the oil temperature and accumulation is monitored by instruments.

8. Heating System

The 5 backboards, installed on the layer press machine, have water hoses cycle routine, which is heated by water as its heating medium, which heat the backboards to guarantee the temperature needed for curing the sandwich panels during the polymerization phase.

Mould Heating Machine

The adopted water heating system, of 50 Kw power, can supply enough hot water according to the requirements.

Heating Hoses

Rubber hoses connect with the mould heating and backboard, and to protect the external wall to make the backboards move in-out freely.

9. Electrical Control

Consists of hydraulic button controls, time-control buttons, as well as protection buttons, which show the working status and there is an inter-lock and auto-lock function.

The curing time for a sandwich panel can be adjusted within 0-30 min according to the polymerization requirements.

10. Mould Frames

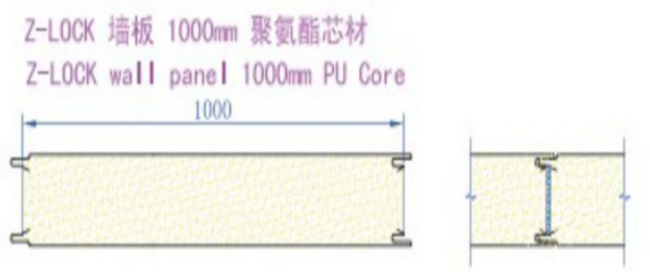

It can produce PU sandwich panels within 1250 mm x 6000 mm x 200mm.

Company Profile

Wuxi HRF Science & Technolog Co.,Ltd located in Wuxi city,Jiangsu province which is close to Shanghai international airport ,we enojoy convenient transportation and advantageous location with which supply good business opportunities for the investors home and abroad.And our company was established in 2009, has the specialized technical team, provides the high quality product and the high quality service for you.

Our company are specialized in designing,manufacturing,sales and services in the field of cold roll forming machines, we can supply the stud-track forming machines,c/z purlin forming machines,roof &wall forming machines,expressway guardrail forming machines, metal deck forming machines ,steel tile forming machines ,PU sandwich panel production line as well as slitting lines and cut-to-length machines lines and so on.

"Copra" software made in Germany is a kind of professional software for designing the cold roll forming machines.In the past years,we devoted ourselves to studying,training and putting into production.Through continous efforts made by our staffs,we already improved a lot on the machines quality and won good repution in the worldwide.

We are ready to establish the business relations with the overseas customers and we also believe" the oppotunity here,here you are"

Our commitment is quality and service , our goal is customer satisfaction . We will, as always, be pragmatic and promote mutually beneficial cooperation and common development Of you

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

3. What is the quality of your machine?

The first class Quality. We manage to offer our partners the best customer care, products and services by using the latest technologies in the branch. The components we provide are of best quality, to make sure our machines can be running very well for decades.

4. What service we can get from your company?

-VIP Service. Due to our standards, we manage to build long-lasting relationships with all our customers. We are 24/7 online available for you to answer your questions and solve your problems.

5. Quality Inspection

The machines of our company have many certificates like ISO 9001, CE, SGS, etc. Before the shipping, we have a series of quality check system, includes 3 times of inspection for every production procedure. First inspection needs the workers to check and sign on the test report. Second inspection involves department leaders to check and sign on the test report. The Third inspection needs professional inspector to check and ensure the machines are qualified. We also give 18 month warranty time to the customer

Related Products

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing. E-mail:

E-mail: Tel

Tel  Add

Add