Wuxi HRF Science & Technology Co.,Ltd

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Description &Function

1、What is Cut To Length Machine The Cut To Length Machine also called cut to length line which are used for uncoiling,leveling and cutting the metal coil into the required length of flat sheet material and stacking.It suitable for processing cold rolled and hot rolled steel, coil,galvanized steel coil,silicon steel coil, stainless steel coil,aluminum coils etc into different width according to the user’s production demands and cut as well

2、Function This equipment through the procedure of uncoiling, leveling, precision gauge cutting, processing the strip steel coil into required steel pate. It mainly composed of uncoiler, pincher and leveler, gauge, cutting machine , stacker, etc, with assists of feeder, side guiding device, transition, and conveyor, etc. 3、Category According to the metal materials there are stainless steel cut to length machine,silicone steel cut to length machine,cold or hot rolled plate cut to length machine and so on. According to its electronic control mode there are pneumatic cut to length line,NC cut to length line and etc..

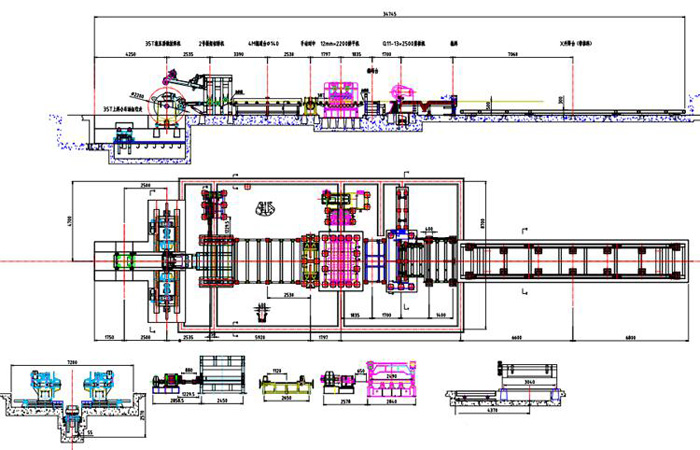

The whole lineflowchart

Coil loading car----Decoiler----coil head press, guide and shovel equipment----Double pinch rollers---Centre aligner----high-precision levelers( 23 rolls)---encoder ----hydraulic tracking cutting machine--pinch rolls for sheets dropping-- plates-delivering roll table----plates sending out device----plates supporting table---plates piling up device--manual packing

Machine parameters

1.Basic Parameters

1) Material of coils: carbon steel,hot/cold rolled coil,galvanized steel coil etc

2) Thickness: 0.5-3mm Width: 500mm-1600mm

3)Mechanical properties: δs=250 δb=350

4)Coil OD, ID: max 2,100mm

5)Max coil weight: 30,000Kgs

6)Cut-to-length precision:

Leveling accuracy: ±0.5mm/㎡

Length tolerance: ±0.5mm/2000mm

Diagonal length tolerance: ±0.5mm/2000mm

Cut to length line speed:50 pcs according to 2m long cut sheet

Line speed:0-100m/min adjustable

2. Composition of the Line

1) Hydraulic coil-loading car (30T)

2) Single mandrel Decoiler (30T)

3) Hydraulic Coil-end feeding, pressing and shoveling device

4) Central aligner

5) Double-roller pinch &main 17 rolls leveller (2+17 rolls)

6)Loop pit

7)Center aligner

8)9 rolls leveller for length measuring(2+2 rolls for length measuring,5 rolls leveling)

9) Flying-shear machine+servo motor

10) Transmission conveyor/belt(3m length)

11) Lifting&Lowering table&pneumatic stacker ( 2 sets )

12)Sheet Unloading coil car( 2 sets)

|

|

|

|

|

|

|

|

Product Advantage

Technological process of the production line is concise, compact layout, advanced technology, put an end to produce defects, comprehensive energy consumption is low, simple operation and maintenance, low operating cost.

2.Production line adopts the standard electrical, instrumentation components and equipment components meet the needs of the buyers,Control system has the maintainability and expansibility; And ensure the advanced technology, reliable control, during normal operation can automatic complete all real-time detection and adjusting function, have interlocking function to prevent wrong operation, Do all the operation, monitoring on main operating platform .Display and handle the alarm.

|

|

|

|

|

|

Certified product

Certified product

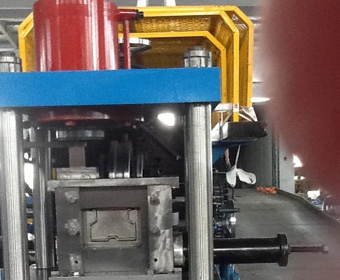

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.○ Cable Tray Forming Machine

○ Door Frame Forming Machine

○ Guardrail Forming Machine

○ Pipe Forming Machine

○ Purlin Quick-Changeable Forming Machine

○ Rack Roll Forming Machine

○ Cotinuous Pu Panel Press Line

○ Discotinuous Pu Panel Press Line

○ Automatic Rotary Shear Machine

○ High Speed Uncoiling-Leveling-Cut To Length -Stacking Line

○ Hr Coil Uncoiling-Leveling Cut To Length Stacking Line

○ High Speed Uncoiling - Slitting Rewinding Line

○ Uncoiling - Slitting - Rewinding Line For Middle &Heavy Thickness

E-mail:

E-mail: Tel

Tel  Add

Add