Wuxi HRF Science & Technology Co.,Ltd

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

Tel:+86-510-81153870

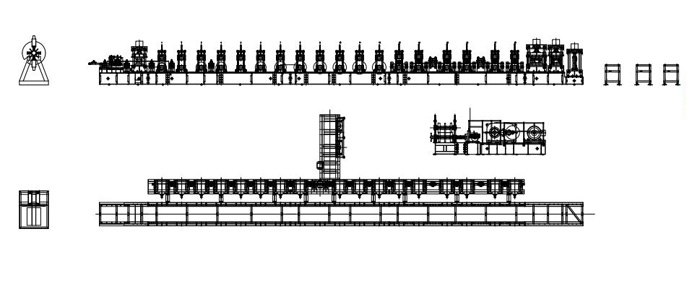

| NO | ITEM | PARAMETER | REMARK |

| 1. | Suitable material | cold rolled steel coil,G350Mpa | |

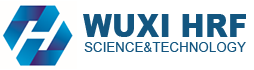

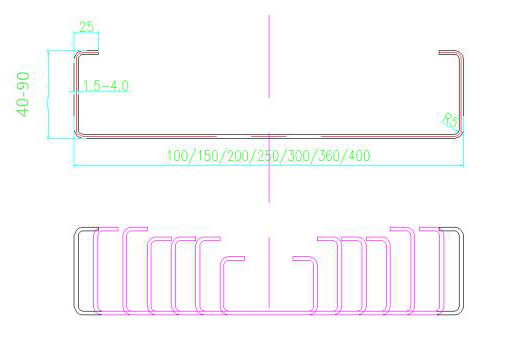

| . 2 | Finished purlin demension |

1)C/Z purlin width: 100-400mm automatic adjustment 2) C/Z purlin flange height:40-90mm automatic adjustment 3)Lip size:25mm 4) Thickness: 1.5-4mm |

|

| 3. | Roll Forming structure | Casting stands structure with 16 nos + series of vertical rollers | Casting stands |

| 4. | Main forming machine motor power(kw) | 30kw | Siemens motor made in china |

| 5. | 9 rolls Leveling motor( 4+5 rolls) | 5.5kw | motor,made in china |

| 6. | Hydraulic station power(kw) for main | 11kw | Motor made in china |

| forming machine | |||

| 7. | Motors for the height adjustment | 1.5kw( 2-0.75kw) | Motor made in china |

| 8 | Motor for purlin width adjustment | 1-1.5kw | Motor made in china |

| 9. | Hydraulic station ( 2 in 1) | 3kw | motor,made in china |

| 10. | Servo-feeder motor for punching | 4.4kw | Yaskawa brand |

| 11. | Servo-feeder motor for moveable cutting | 7.5kw | Yaskawa brand |

| 12 | Motor for motorized table | 2.2kw | |

| 13 | Total power(kw) | About 67kw | |

| 14 | Power supply requirement | 380V,50Hz,3Ph | |

| 15 | Machine dimension(LxWxH,m) | 31mx2.5mx1.6m | |

| 16 | Machine color | Blue with yellow color combination | |

|

|

|

|

|

|

|

|

|

|

|

|

Certified product

Certified product

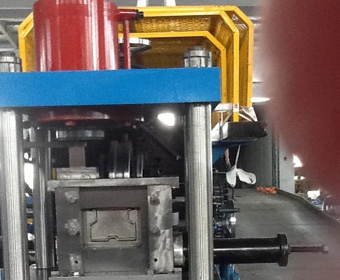

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.○ Cable Tray Forming Machine

○ Door Frame Forming Machine

○ Guardrail Forming Machine

○ Pipe Forming Machine

○ Purlin Quick-Changeable Forming Machine

○ Rack Roll Forming Machine

○ Cotinuous Pu Panel Press Line

○ Discotinuous Pu Panel Press Line

○ Automatic Rotary Shear Machine

○ High Speed Uncoiling-Leveling-Cut To Length -Stacking Line

○ Hr Coil Uncoiling-Leveling Cut To Length Stacking Line

○ High Speed Uncoiling - Slitting Rewinding Line

○ Uncoiling - Slitting - Rewinding Line For Middle &Heavy Thickness

E-mail:

E-mail: Tel

Tel  Add

Add